High Productivity

GEORG is your partner for high productivity of cutting lines for your transformer and electric motor production as well as roll grinding machines for battery production. The high cutting and grinding quality, the simple and low-personnel operation of our machines and our comprehensive service including training make us a sought-after supplier worldwide.

Our solutions enable our customers to achieve high productivity and reliability, which we have been demonstrating day in, day out for many years at renowned companies around the world.

Your Benefits

- High productivity

- Short set-up time

- Low man-power

- Low maintenance

- High energy efficiency

- High work safety

Why GEORG?

- Decades of experience in electrical steel

- Fulfilling highest quality requirements

- Highest productivity solutions

- Highest grade of automation with IoT applications

- Latest energy saving features

- Setting new standards for strip monitoring

More Value

GEORG Product

- Increase in profitability

- Increase in process reliability

GEORG protectionworld

- Reduction of operating costs

- Increae in the rate of return

GEORG consulting

- Expansion of competitivness

- Technology optimization

- Process optimization

GEORG digital

- Predictive maintenance

- Condition monitoring

- IoT

- GEORG dashboard

Our Products for Electrical Steel

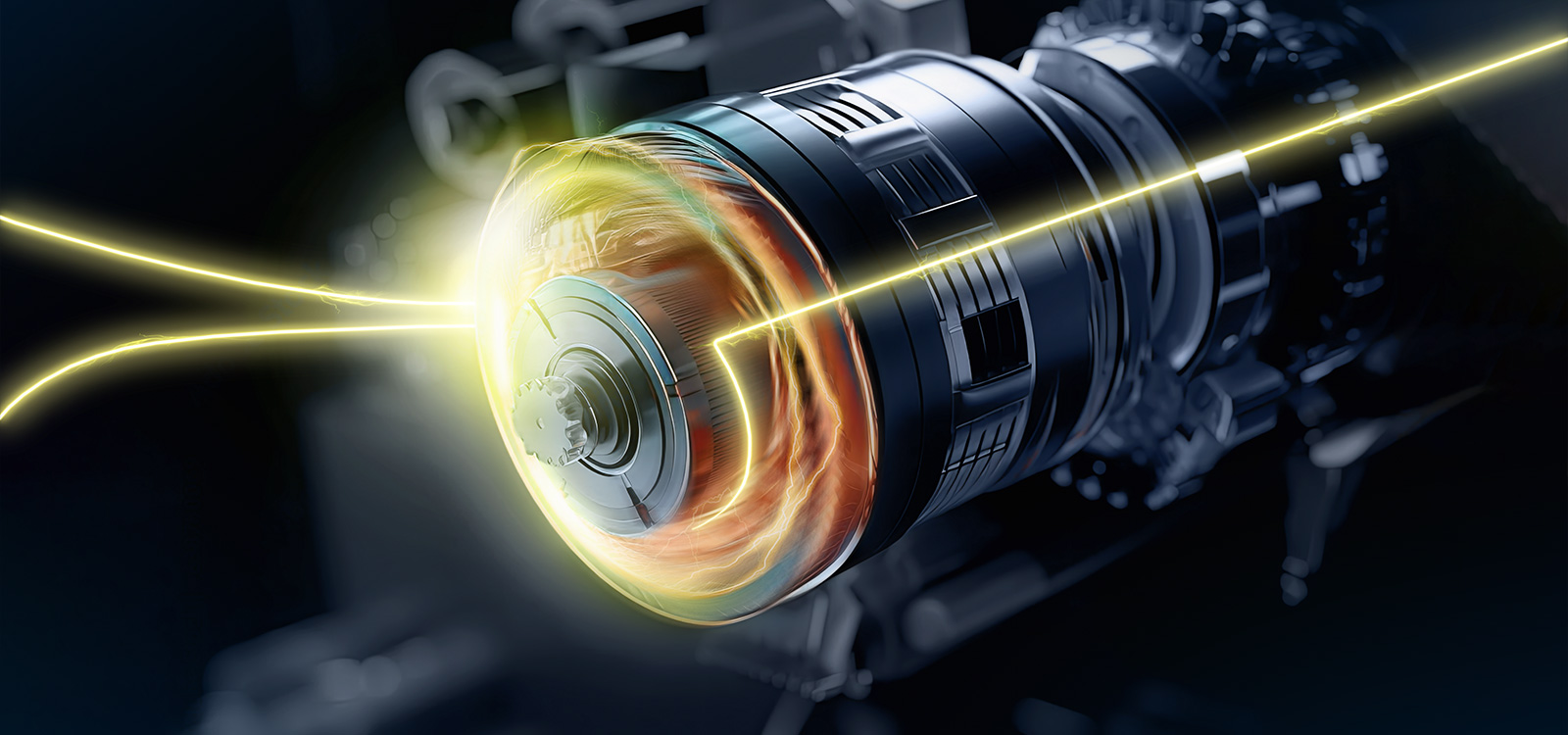

From flat rolled coil to core and motor

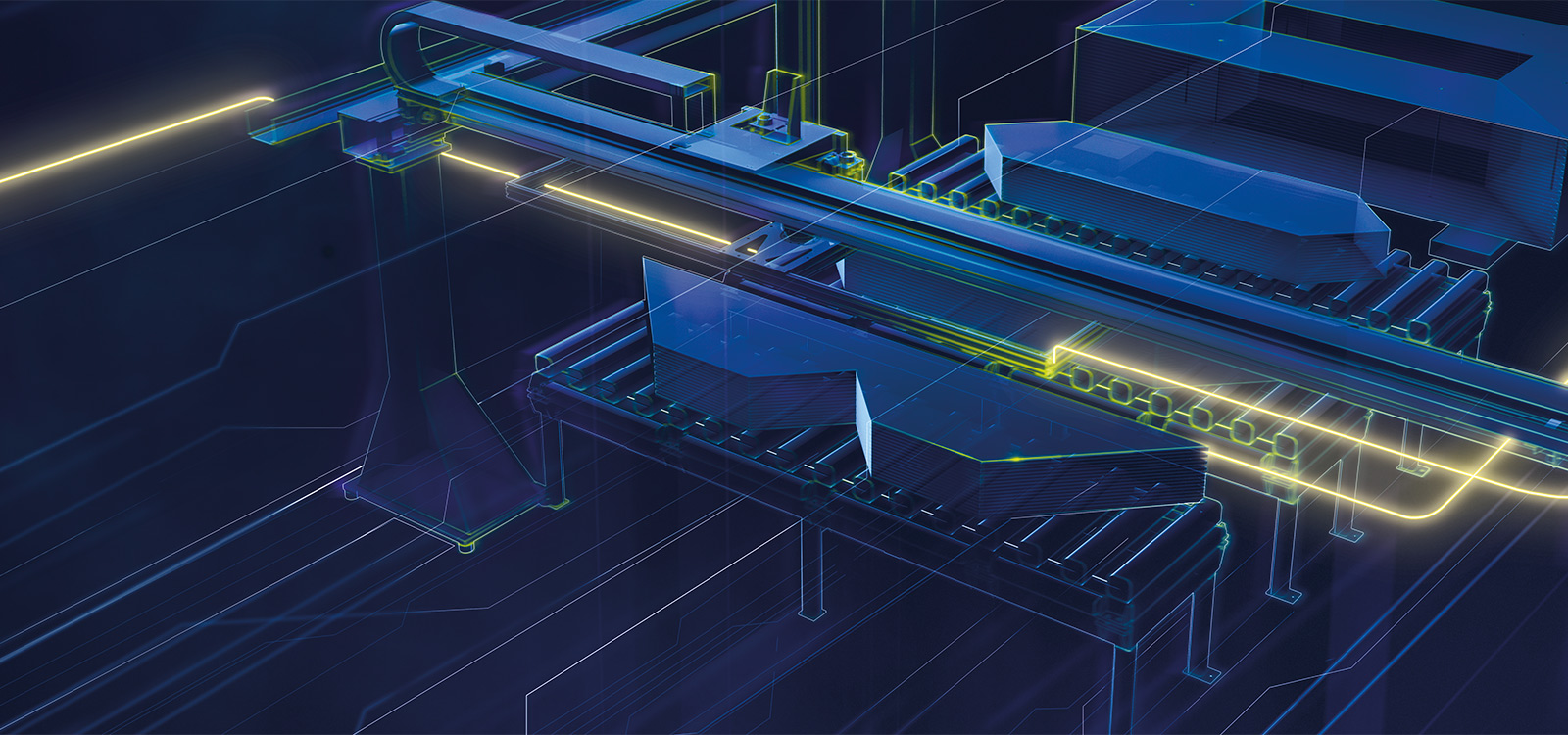

Slitting lines for electrical steel

GEORG precisionslit

Slitting lines of the GEORG precisionslit TRA series for electrical steel impress by highest slitting accuracy as well as mimimum burr and curvature.

- Highest capacity

- Highest flexibility

- Highest automation combined with highest accuracy

Quickfacts

Coil weight

up to 30 t

Strip width

up to 1,650 mm

Line speed

up to 400 m/min

Strip thickness

from 0,10 mm to 1,00 mm

Other Products

GEORG presicionslit

GEORG precisionstack

GEORG inspectionlines

Cutting lines for transformer core lamination

GEORG precisioncut TBA

Our TBA cutting lines for transformer core laminations cover a wide field of applications. Our GEORG robotline enables the fully automatic in-line stacking.

- Low burr, loss quality lamination for high quality transoformer cores

- Equipment options for precise manual or automatic core assembly

Quickfacts

Strip width

max 300 – 1,200 mm

Line Speed

up to 190/laminations per minute

Sheet length range

from max. 1,200 – 1,600 mm

Other Products

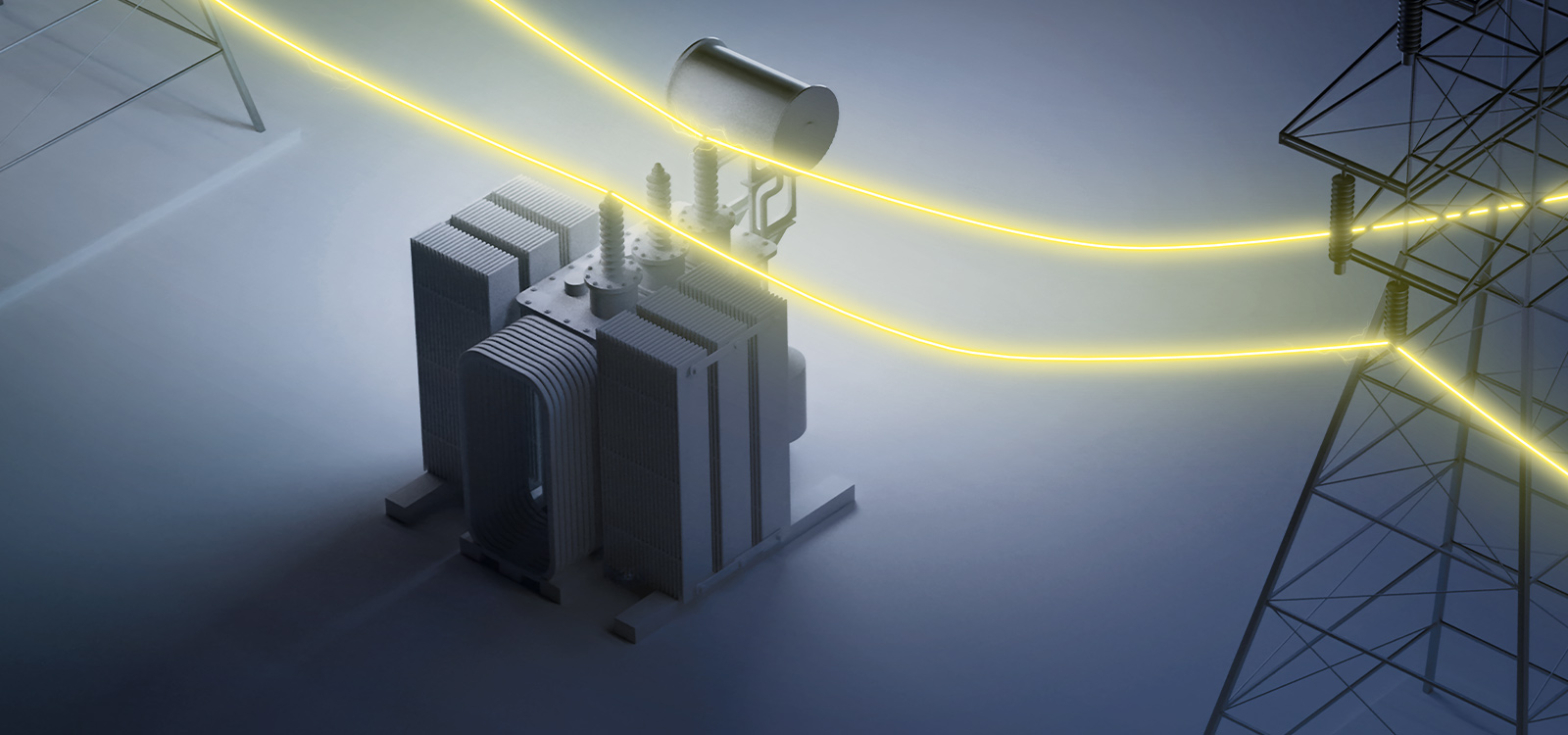

GEORG ultragrind

The machines of the GEORG ultragrind series are supplied with the GEORG smartcontrol and meet the next step of digital transformation.

- Highest accuracy for grinding back-up and work rolls

- Integrated measuring system

- Integrated GEORG smartcontrol

Quickfacts

Workpiece weight

max. 25 t

Roll diameter

max. 1,500 mm

Roll length

max. 6,000 mm

Other Products

Get in contact

GEORG protectionworld

Life Cycle Quality Management